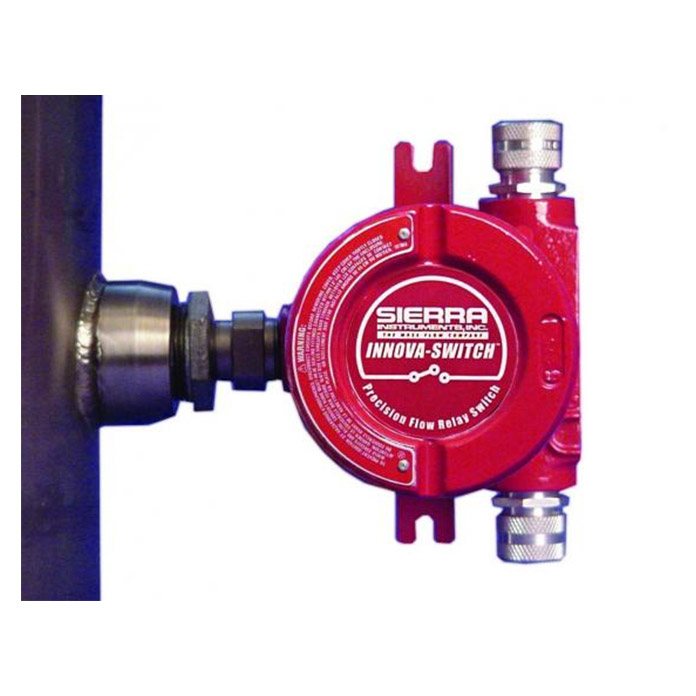

Level Switch - InnovaSwitch™ 615-LS32

/Level Switch for Liquids

Indicates liquid level in tanks and process vessels. Switches on level change of 0.03 inch (.08 cm) (dry to wet and wet to dry)

Response Time: 0.1 to 1 second (media dependent).

Wide operating temperature range of -100F to +390F (-70C to 200C). CE, CENELEC and CSA approvals.

InnovaSwitch 615-LS42

Technical Details

- Liquid Level Switch for the detection of the liquid level in tanks and process vessels

- Level switch response time of 0.1 to 1 second of wetting (media dependent)

- Wide operating temperature range of -100F to +390F (-70C to 200C)

- Operating Pressure: to 3000 psia (207 bar)

- CE, CENELEC and CSA approval

- Repeatability: +/- 1% of set point (Flow) or 1/32î (0.8mm) Level

- Stability: Drift <0.5% from calibrated set point over a range of +/-50F

- Temperature compensated through entire range

- Enclosure: Explosion Proof; NEMA 3, 4X, 7, 9. CSA, FM, UL, CENELEC and EECS approved

- Process Connection: 0.75" MNPT standard. 0.5" and larger MNPT and various other process connections such as sanitary and flanges optional

- Insertion Length: 2.0" standard. 0.5" or greater optional

- Input Power: 115 VAC, 50/60Hz standard. 230 VAC, 50/60Hz optional, 24VDC optional. 3.1 Watt maximum

- Output: 5A. 250 VAC. DPDT with fail safe capability

Operating Principle

The thermal differential created between the heated and reference unheated RTD pair is a function of the liquid or gas medium with which the sensor is in contact.

The point level measurement application uses the heat transfer differences between two media to detect liquid level. For example, air has a relatively poor heat transfer characteristic so the heated sensor will become relatively hot. If the sensor is then immersed in water, the relatively high heat transfer characteristics of water will cool the heated RTD surface causing a decrease in the signal output.

This same rational applies for any two media in contact with the sensor. Each medium will have its own characteristic heat transfer properties. As long as there is a reasonable difference in the heat transfer properties between the two media, the Innova-Switch™ can discriminate between them. Figure 2A shows the relative signal output of the Innova-Switch™ sensor to a range of different media. The maximum difference in output occurs between vacuum and liquid metal. However, a significant difference occurs between water and hydrocarbon liquids so the InnovaSwitch™ can be used to detect a water/hydrocarbon liquid-liquid interface. In general, the interface between any two media with differing heat transfer properties can be detected.